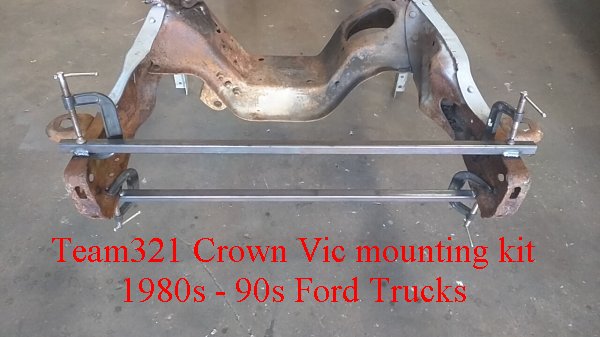

Installation info for Team321 Crown Victoria mounting brackets – 1980 – 96 Ford trucks

For more information…Call (321)960-5945 or email dave@team321.com

The price is $475 including shipping in the US.

For Installation videos… check out JMR Rebuilders on Youtube:

The kit contains 1 passenger’s side C channel… 1 driver’s side C channel… 4 Crush tubes… 2 trailing arm mounting plates.

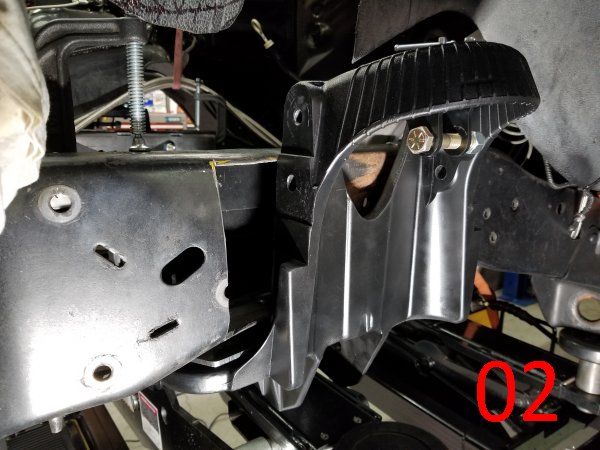

Here is another view of the same components showing how the crush tubes fit in the C channels

As 1980s and 1990s ford trucks become more affordable and available, these install kits will be highly desirable. I want to get ahead of the demand and provide the best product that I can. Your participation in fitting my products will ensure that… and in turn, I will continue to evolve and improve the fit and installation ease of these products.

Prior to removing the factory steel crossmember, be sure to weld a crossbar to secure the frame rails.

In 1980, Ford changed the design of their truck frames. The frame rails are not parallel, nor are the frame rails symmetric. Due to these features, development of a kit to mount a Ford Crown Victoria (Crown Vic) factory crossmember was a challenge. The aluminum factory Crown Vic crossmember mounts via 4 bolts (2 on each side) and utilizes alignment pins on the lower mounting interfaces to locate the crossmember on the truck’s frame. These 4 long bolts pass through the trucks C-channel frame – top to bottom. Due to the nature of the mounting, ‘crush tubes’ are used to strengthen the C-channel frame.

Team321 provides a set of brackets to locate the alignment pin and locations of these crush tubes to mount the factory Crown Vic crossmember. The original, factory steel crossmember must be removed… all the rivets removed. This is a very time-consuming process. Removing the rivets involves cutting them with a cutoff wheel / grinder… then punching them through with a mini sledge hammer and punch. I have also used a plasma cutter and air hammer, but that really messes up the factory holes and may negatively affect the install.

The pic below shows the Ford truck factory frame rails relative to where the material – brackets – must be added to support the crossmember. Note the FWD crush tube is barely in contact with the frame rails…

To properly locate the crossmember the included C channels have the same hole pattern as the factory frame rails. These holes are 3/8″ and 1/2″ diameter. The idea is to position the C Channel on top of the factory frame rails… Bolt the C channel in place using your bolts… Then use a hole saw to make holes in your truck’s frame for the crush tubes.

After making the crush tube holes in the tops of the frame rails… relocate the C Channel under the lower frame rail and repeat the process to make holes in the frame rail for the crush tubes and alignment pin.

Note the L indicates the Left or Driver’s side C channel

Another View of the Driver’s side showing that material must be removed to clearance the frame for the Crown Vic subframe and the upper control arm mount. This Gap MUST be replaced with steel reinforcement to complete the install.

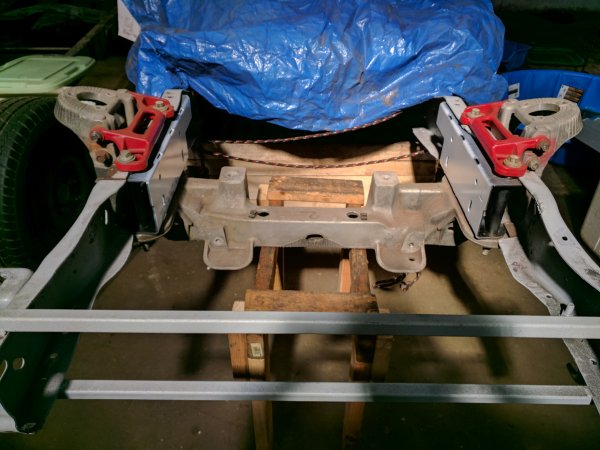

A view from the front showing the crossmember installed and the gaps that exist that must be filled to complete the install. Additional boxing must be done by you, the customer.

This View from the passenger’s side shows the relative position of the factory frame rail and the Team321 C Channel… you will also discover that the lower portion of the frame rail AND the upper portion of the frame rail must be trimmed to make it “flat” to properly accept the C Channel and Crown Vic subframe. This be done by making Pie cuts and bending the factory frame rail up / down as necessary.

Inside view of the passenger’s side

Outside view of passenger’s side

Now that you have two crush tube holes – top and bottom… and one alignment pin hole on the bottom – on each side… It’s time to test fit the aluminum crossmember. Material must be removed from the frame on the Driver’s (Left) side to allow for clearance of the aluminum crossmember. The driver’s side frame rail kicks out – to provide clearance / mounting for the steering box… but since that’s no longer required, it just gets in the way of the Crown Vic aluminum crossmember.

Additionally, you must remove material from the frame to clear the Upper Control arm bushings. Here is a picture of the forward end of the Driver’s side Upper control arm. The bolt that mounts the upper control arm cannot be inserted due to the interference between the upper control arm and the frame rail. This must be clearance before proceeding

Now that the frame has been clearanced for the subframe… re-assemble the C Channel to position the crossmember. The LOWER portion of the C Channel fits UNDER the frame rails and UPPER portion of the C channel fits INSIDE the truck’s C channel. The reason for positioning the Team321 C channel under and inside the truck frame’s C Channel is to position the crush tubes to be the proper length for the Crown Vic subframe… This design assumes you are using the crown vic’s hinged upper mount.

Assuming you are happy with your new suspension’s location, tack weld the supplied bent plates, crush tubes, dog bones to your truck’s frame.

Team321 LLC supplied C channels and crush tubes are a starting point. The frame rails on 1980s and 1990s Ford trucks require boxing to support the Crown Vic front crossmember. You MUST add material to box in your frame rails. Please send pictures of your boxing plates so that we may provide them to others.

The installation of the C Channels is complete… What remains is to strengthen the frame rails by adding material (steel plate) to box the frame rails. It is very important to box the frame rails with additional steel plate beyond the boxing done by the provided C Channels

In closing – the more information you provide in pictures and feedback, the better the product for you and others.

Here are some additional Customer-provided images. This type of feedback is incredibly valuable and will lead to a better product. This multi-piece assembly to mount the Crown Vic crossmember is an intermediate design. The ultimate goal is to provide a pair of C –Channel frame rails to fit the factory frame and properly locate the Crown Vic crossmember… but such an investment cannot / will not be made until I’ve accumulated the proper amount of feedback from customers. I simply cannot purchase, strip and test fit all possible variations of ford trucks from 1980-97 to assure proper fitment, so I’m depending on customers to provide such feedback… and I thank you in advance for that info.

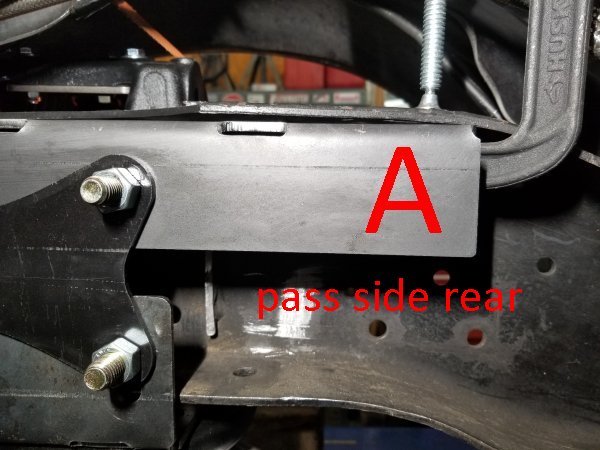

This image shows the passenger’s side rear… notice in the upper right corner, the bent plate does not precisely interface with the top of the truck’s C channel frame rail. The frame rail will need to be notched to relieve that interference.

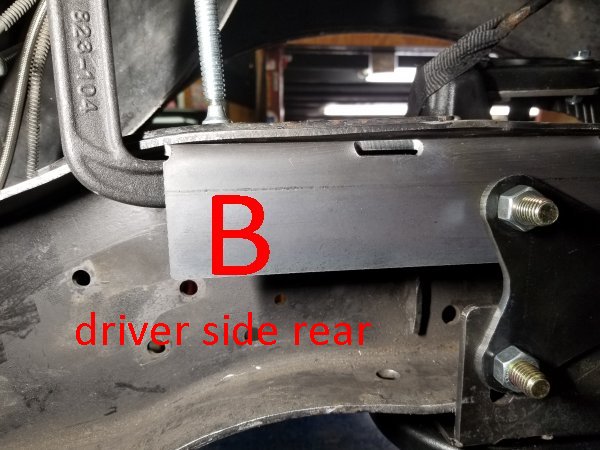

Same interference on the Driver’s side…

Again, feedback is key. This is a customer-provided photo showing a mod to one of the mounts. Trimming off the tiny bit is not a big deal, but all it takes is one customer to provide this information to me… I update the drawings and all subsequent parts are created correctly and no longer need any mods… they are install-ready.

The FWD edge of the lower mounts interfere with the truck’s C-channel frame rails… Requiring the C-channel to be trimmed to allow a proper, flat interface of the Crown Vic crossmember. Here is a picture of the interference prior to clearancing.

And here is a pic after the frame rail was modified.

Another shot showing the amount of frame rail that must be trimmed and subsequently patched to allow clearance for the Crown Vic crossmember.

and here’s a view of the patch… great fab work!

and another one after paint and crossmember fitment

For more information…Call (321)960-5945 or email dave@team321.com

Back to Team321 Homepage

Back to Team321 Homepage